Navigation

VA7 installation

Fixing VA7 to the machine bed

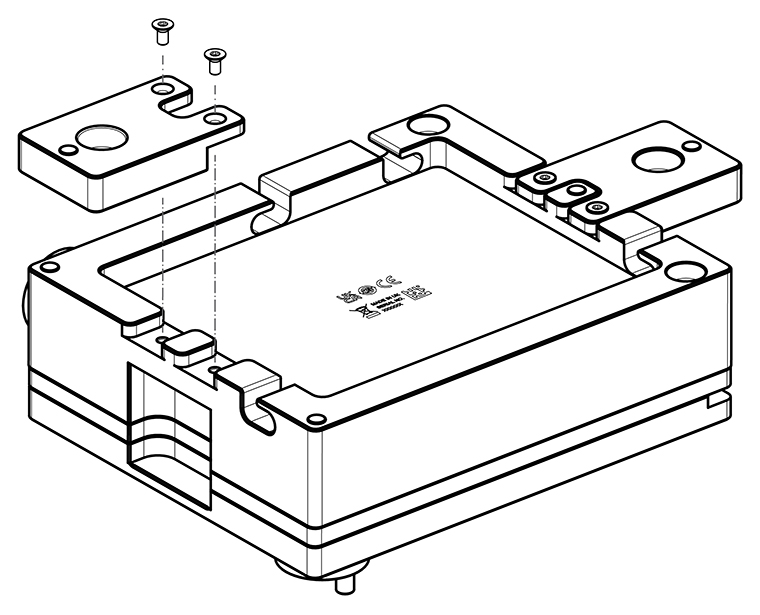

The VA7 artefact is designed to be fixed securely to the bed of the machine. Bed clamps and mounting bolts are supplied in the kit for use with CMM frames with 100 mm separation of threaded inserts. For machine beds with different threaded insert separation, other suitable bed clamps can be used.

Fixing VA7 using supplied clamps

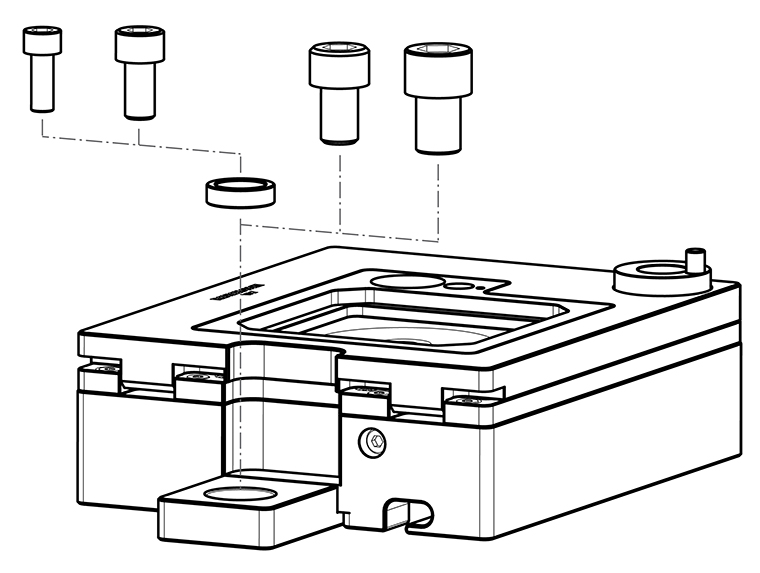

For CMM frames with 100 mm threaded insert separation, it is recommended to use the bed clamps supplied in the VA7 kit. The diagrams below show how to use the clamps.

1. Attach the bed clamps to the VA7 artefact using the four off M3 countersunk screws provided.

2. Affix the VA7 artefact to the machine bed using the M6, M8, M10 or M12 bolts provided. Washers are provided for use with the M6 and M8 bolts.

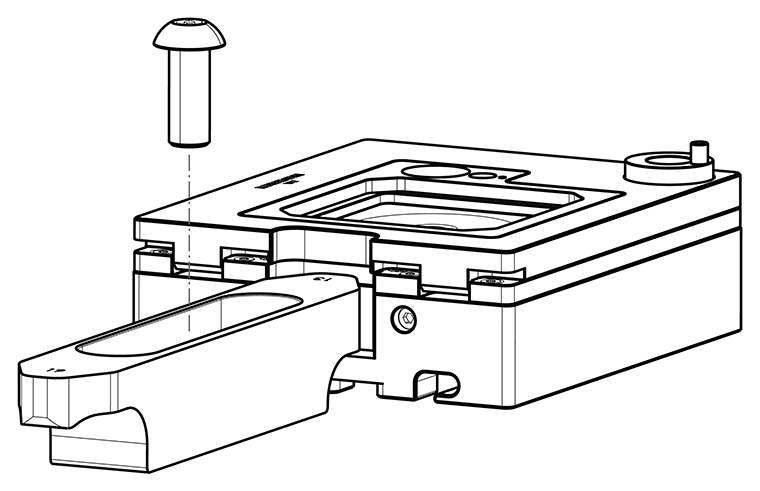

Fixing VA7 using alternative CMM clamps

The VA7 artefact can be secured to the CMM bed with any suitable CMM clamp using the clamp slots on each side of the artefact. Renishaw recommend the use of the R-CPC-190 CMM plate clamp. The VA7 bed clamps should first be removed, if fitted, before using the plate clamps. The diagram below shows how to use the clamps.

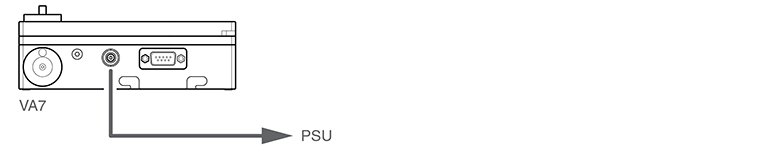

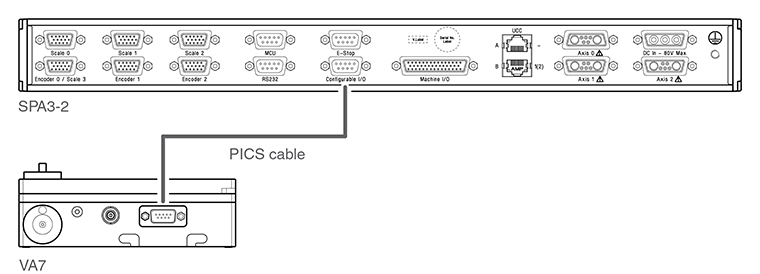

Connection diagram

The VA7 artefact should be connected as shown in the diagrams below. On an installation where a UCC AI / UCC BI is required, contact Renishaw for further information.

VA7 and SPA3-2:

VA7 and 24 VDC 70 W PSU connection: